Founded in 1986 by Roberto Motti, Centrufficio started out from a small shop in the heart of Milan and, currently has 22 showrooms in Italy, 189 employees and a turnover of around € 53 million.

It manufactures design office products and deals with everything related to the workplace: from design to turnkey (general contractor), from the creation of bespoke projects and products, including acoustic projects.

It has a central warehouse in Pioltello MI of about 20,000 square metres and therefore ensures, for many products, furniture and wall partition walls in prompt delivery.

Click here to download Company Profile 2025 Video presentation

Presidente del C.d.A.

Vicepresidente del C.d.A.

VALUES AND MISSION

1. Customer Satisfaction.

1. Customer Satisfaction.

Our customers are our greatest resource, their satisfaction is our primary goal. They are the value of our business.

2. Designcracy

2. Designcracy

The creation of beautiful, design objects at affordable prices for ‘democratic’ design.

3. Commitment to the environment

3. Commitment to the environment

Making products that have an increasingly low environmental impact, guaranteeing quality products and made in Italy.

40 YEARS OF HISTORY

1986

Opening of the company Roberto Motti is the founder

1988

Opening of the second showroom in Pavia and the first warehouse in Cologno M.se (MI)

1996

The production of office furniture and seating begins

2000

The production of partition walls begins

2003

Opening of the second warehouse in Segrate (MI)

2010

Online store opening

2014

Opening of the 20th showroom (Florence)

2016

30 years of activity

2018

Collaboration with designers: Progetto CMR, J. Bennett, S. Adachi and D. Lo Scalzo Moscheri

2019

Inauguration of the new headquarters in Pioltello (MI), with state-of-the-art warehouse and machines

2019

CUF MILANO showroom opening in Milan, Corso Como area.

2023

Opening of the “Engineering” division

(Centrufficio Impianti)

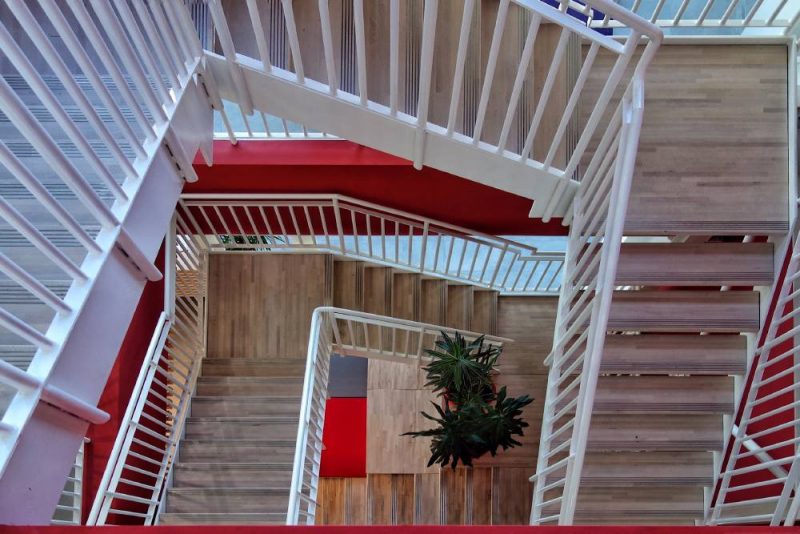

NEW CORPORATE HEADQUARTER

Pioltello Mi – Via Sondrio, 10

A GREEN ORIENTED company. Building in energy class A.

Building realized on Project and Works Management of Apiuc – Arch. Pier Alberto Ferrè.

The Architecture Studio has also carried out the hydrogeological survey, the environmental impact, the seismic risk and has received the approval of the Landscape.

PHOTO GALLERY

SUSTAINABILITY

For some years now Centrufficio S.p.A. have been engaged in a process of limiting the effects that their production can have on the environment.

The “production interventions” concern all those operations which are carried out in order to limit the possible harmful effects on the environment due to the use of machineries, transports and energy resources which are used during the normal working activity.

Thanks also to the achievement of the environmental certification UNI EN ISO 14001, in this area are collected all the structural interventions related to headquarters, transport and machinery, such as:

- Installation of photovoltaic panels at the warehouses in Cologno, Pioltello, Modena and Vicenza as well as the branches in Brescia, Modena and Vicenza;

- Installation of electric car refuelling points at Pioltello headquarters and purchase of the first electric cars, which will gradually replace the entire fleet of around 60 vehicles;

- Promotion among its employees of the use of green vehicles, first and foremost bicycles, for which there is a special parking lot and bicycles available;

- Creation of a green area at the new headquarters in Pioltello of approximately 2,000 square meters, of which 200 square meters are used as a vegetable garden, cared for by the employees themselves, who have the right to harvest the vegetables for their own use and consumption;

- Use of low-consumption LED lights in all offices, as well as double or triple-glazed windows with low thermal transmittance profiles for energy savings in both summer and winter;

- Promotion of minimum use of paper and toner to all employees.

The “product interventions” concern the raw materials and packaging used in the production of our products. Centrufficio S.p.A. was one of the first companies to comply with the Minimum Environmental Criteria, promoted by the Italian Ministry of the Environment, which include a series of requirements regarding the use of formaldehyde, volatile organic compounds and other potentially harmful substances.

Our melamine panels are CARB-certified, with very low formaldehyde emissions, and the coatings used are epoxy powder coatings that do not contain volatile organic compounds.

NO PLASTIC IS USED for the packaging, apart from a light film on the glass tops to prevent scratches and to hold together any high pallets: the corner pieces that repair all of our panels are made of cardboard, as are the packaging itself, from all of our own production lines.

Download the Sustainability Report 2023

THE FACTORY

Our production is based in three different places, all in Italy:

- Motta di Livenza (Treviso), where we produce semifinished products;

- Mombaroccio (Pesaro-Urbino), where we realize industrial on demand items;

- Francenigo di Gaiarine (Treviso), for packaging operations.

Our organization has three different production: industrial production, middle-business and carpentry lab, to satisfy all the Client needs.ciclo industriale, la media impresa e il laboratorio di falegnameria per soddisfare le specifiche esigenze di ogni Cliente.

industrial producion we use big machineries for series production, so we can guarantee good quality with low prices, and ready-to-delivery items

middle-business we use numeric-control machines, committed to special furniture or to restricted lines.

carpentry lab we have a special department, with designers and carpenters, that creates totally “on demand” furniture, based on the specific Client needs.